The project is funded within the Horizon Europe program (CINEA) with Project ID – 101147799

The aerospace industry is poised for significant transformation, driven by the urgent need to enhance safety measures and reduce environmental impacts. The UPBEAT project is at the forefront of this revolution, a collaborative endeavor that epitomizes innovation and dedication to advancing aviation technology and safety. The UPBEAT project, short for Uncertainty Prediction & Bias Elimination in Aviation Technology, is a groundbreaking initiative funded under the Horizon Europe framework.

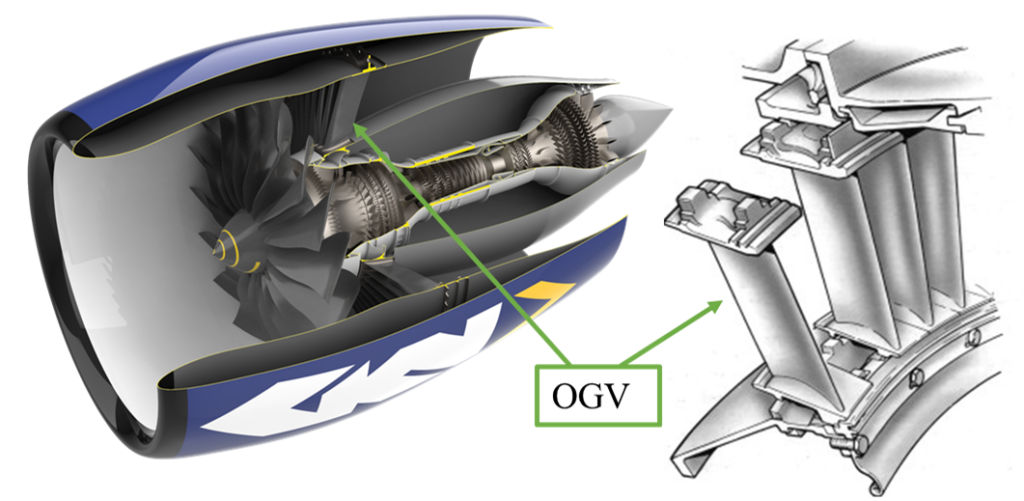

Goals and Objectives: UPBEAT’s primary goal is to integrate advanced uncertainty quantification (UQ) methods into the lifecycle of aircraft components, focusing on the Outlet Guide Vane (OGV) used in turbofan engines. The project aims to enable the EU aircraft industry to design and manufacture disruptive aircraft structures with enhanced prediction capabilities. This will expand the design space and reduce uncertainties associated with product and engineering lifecycles.

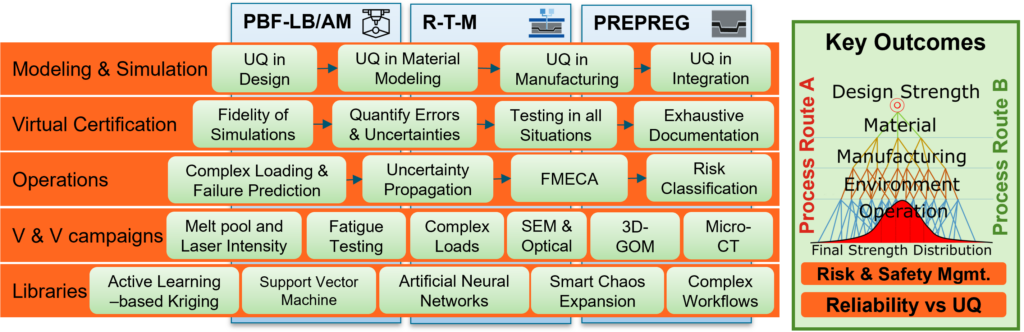

The project targets several key innovations:

◉ Material and Process Modeling: Advanced metallic and composite components modeling incorporates uncertainties from design → manufacturing.

◉ Integration Techniques: We are developing effective ways to integrate composite vanes with metallic components using cutting-edge additive manufacturing and bonding techniques.

◉ Simulation and Validation: Implementing multiscale simulations to understand how design and manufacturing variations influence the final product, ensuring reliability and safety.

The UPBEAT project is set to deliver substantial effects:

◉ Enhanced Safety and Performance: UPBEAT will significantly improve aerospace component safety and performance by quantifying uncertainties.

◉ Reduction in CO2 emissions: The project contributes to the aerospace industry’s efforts to decrease its carbon footprint by optimizing manufacturing processes and reducing material waste.

◉ Economic Benefits: Aerospace manufacturers and suppliers will benefit from reducing the time and cost associated with qualifying their aircraft components.

Looking forward: As we progress with the UPBEAT project, we invite industry stakeholders, researchers, and the aerospace community to engage with us. We can collectively drive the industry toward a safer, more efficient, and sustainable future by sharing insights, challenges, and successes.

The UPBEAT project is not just about technological advancement; it’s about shaping the future of aviation—a future where safety and sustainability are inextricably linked and where every flight is a testament to innovation’s power.

Stay tuned for more updates as we progress on this exciting aerospace innovation journey!

The project is funded by the CINEA See Project Description: https://cordis.europa.eu/project/id/101147799

Consortium: This project is coordinated by SINTEF Manufacturing, and has Aerobase Innovations AB, INSTITUT DE RECHERCHE TECHNOLOGIQUE JULES VERNE, GKN Aerospace Sweden AB, RISE Research Institutes of Sweden, and Phimeca as partners. EASA – European Union Aviation Safety Agency provides technical advice. Aerobase Innovations AB will work with AM simulation and Ti-6Al-4V material modeling.

Connect 🔗contribute.

Are you interested in learning about UPBEAT or participating in its various phases? Please get in touch with us and share your thoughts.