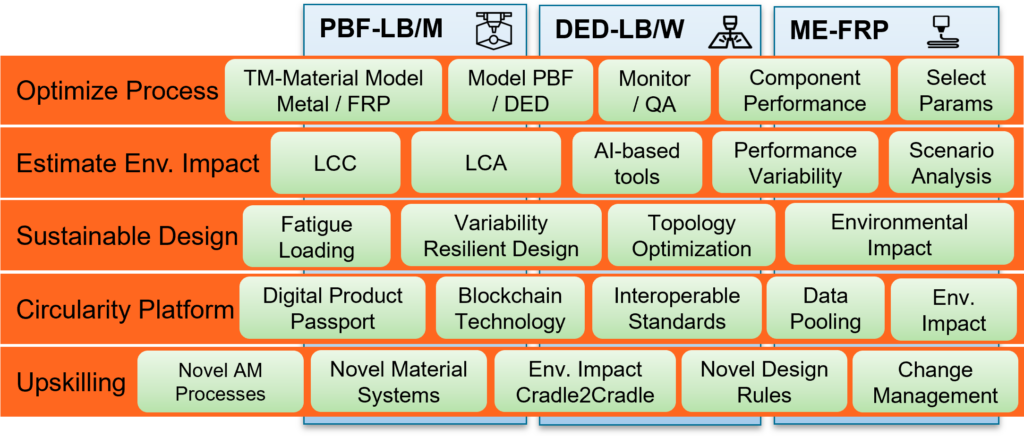

The GEAR-UP project, funded within the Horizon Europe program (HADEA) with Project ID – 101178484, is an ambitious initiative to advance manufacturing sustainability goals. A significant aspect of the project focuses on using recycled materials, such as stainless steel, aluminum alloys, and fiber-reinforced plastics, in additive manufacturing (AM) processes. This project also aims to address the inherent variability in these materials, ensuring that recycled components meet the same performance standards as their virgin counterparts.

Tackling Material Variability through Advanced Modeling

One key challenge of recycled materials in manufacturing is their inherent variability. Trace elements in recycled metals and composites can significantly affect the mechanical properties of the final product. GEAR-UP addresses this by developing sophisticated material models that account for this variability.

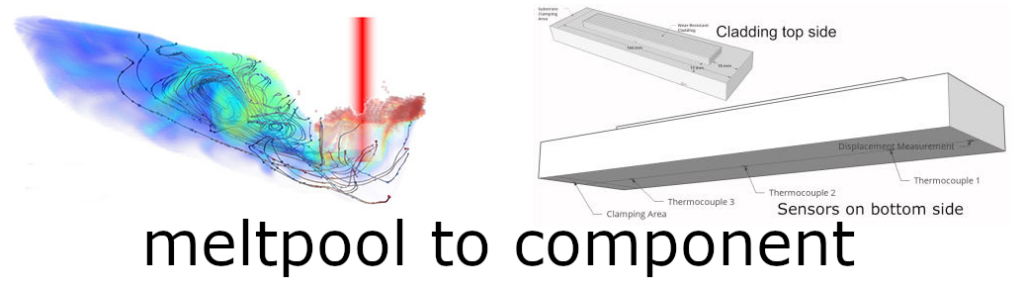

For instance, stainless steel and aluminum alloys used in laser beam powder bed fusion (PBF-LB) and directed energy deposition (DED-LB/W) often contain trace elements that impact the alloy’s microstructure and mechanical behavior. These elements can lead to solidification cracking and non-metallic inclusions, compromising AM components’ integrity.

To mitigate these challenges, GEAR-UP employs predictive modeling to optimize AM processes. These models allow the simulation of trace elements affecting the manufacturing process and final product quality. Adjusting parameters like laser power, speed, and cooling rates helps AM parts retain their desired properties despite material variability.

Advanced Process Modeling for Fiber-Reinforced Plastics

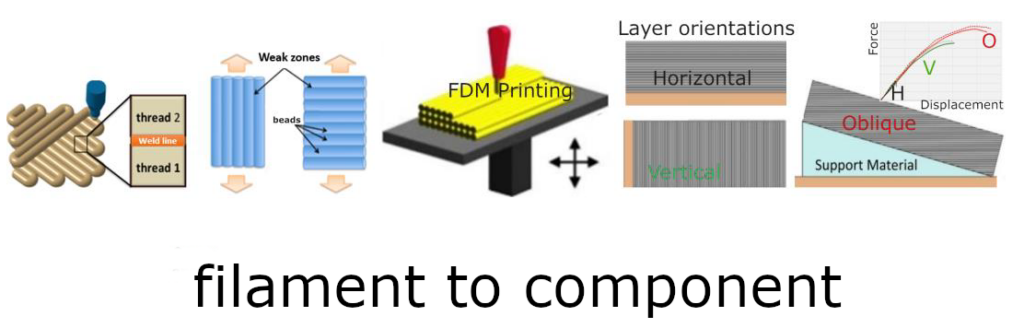

In addition to metals, GEAR-UP also focuses on fiber-reinforced plastics (FRP) used in material extrusion (ME) processes. Recycled polymers often exhibit significant performance differences compared to virgin materials.

To address this, GEAR-UP is developing an advanced process model that incorporates anisotropic data—accounting for the different behaviors exhibited by the material in various directions during the printing process. This model considers factors like infill patterns, layer adhesion, and printing direction to predict 3D-printed parts’ mechanical performance. The ultimate goal is to create lighter, cost-effective components that maintain high performance even when using recycled materials.

Sustainable Product Design with Topology Optimization

The project employs topology optimization techniques to reduce material usage and minimize weight while ensuring sufficient strength and durability, which is particularly critical when using recycled materials. The topology optimization method used in GEAR-UP accounts for fatigue life, material cost, and environmental impact, creating a balanced design that meets performance and sustainability objectives. GEAR-UP’s modeling methodologies represent a significant step forward in sustainable manufacturing by addressing recycled materials variability, optimizing additive manufacturing processes, and incorporating AI-driven environmental impact forecasting. These innovations are expected to profoundly impact industries such as high-performance consumer products, robotics, and green energy, driving a shift towards eco-friendly production methods. GEAR-UP is about creating a paradigm shift in how we approach manufacturing, where sustainability, performance, and resource efficiency work together.

Our tasks: Aerobase Innovations AB plays a crucial role in the GEAR-UP project by focusing on advanced additive manufacturing (AM) technologies, specifically process optimization for stainless steel and aluminum alloys with high recycled content. AER is responsible for developing specialized methods to handle material variability due to trace elements in recycled metals. This ensures that the final AM components maintain high quality and performance standards. Their expertise in optimizing laser power, speed, and other parameters for metal AM processes helps overcome challenges like solidification cracking and non-metallic inclusions in the final parts, ensuring structural integrity and durability.

The GEAR-UP project is funded by the European Health and Digital Executive Agency (HaDEA).

Consortium Partners: The GEAR-UP consortium includes several key partners from across Europe, each bringing unique expertise to the project. SINTEF Manufacturing (Norway) coordinates the project, leading digital manufacturing and sustainability efforts. Flowphys AS (Norway) and Fraunhofer SCAI (Germany) contribute expertise in standards for digital tools. Eurecat – Technology Centre (Spain) brings experience in material testing and powder production, while Welding Alloys France (France) focuses on developing wires with novel material compositions mimicking recycled material. EIT Manufacturing (Italy) supports workforce training and upskilling initiatives. CelluCircle (Sweden) specializes in recycling fiber-reinforced polymers, contributing to circularity in manufacturing. Colfeed4print (Spain) will develop innovative filaments using recycled metal oxide powders. Technovative Solutions LTD (TVS) (UK) will create the digital product passport system. Aker Solutions (Norway) and 3D Production AS (Norway) offer additive manufacturing process integration and application expertise.

Connect 🔗contribute.

Are you interested in learning about GEAR-UP or participating in its various phases? Don’t hesitate to get in touch with us and share your thoughts.