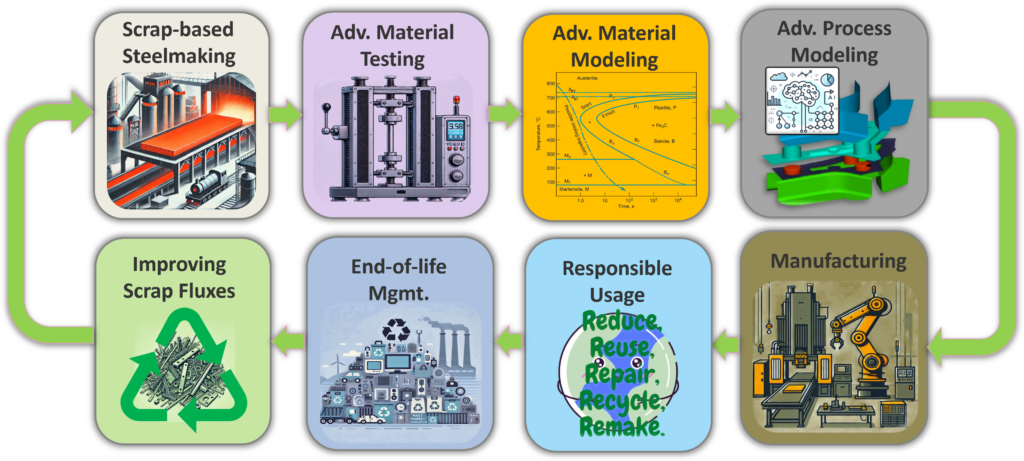

At Aerobase Innovations AB, we are proud to contribute to the CiSMA project, an ambitious initiative to develop cutting-edge solutions for sustainable automotive manufacturing. Focusing on using recycled materials for high-performance steel components, Aerobase is leveraging its expertise in material modeling and finite element analysis to address the challenges of trace elements in recycled steel.

Our team is dedicated to pioneering innovative methods that push the boundaries of traditional manufacturing.

The Challenge: Recycled Steel and Material Variability

As the demand for recycled materials grows due to environmental and economic factors, scrap-based Electric Arc Furnace (EAF) steel is becoming essential in the automotive industry. However, one of the biggest challenges of using recycled steel is managing the impact of trace elements, such as Copper, Tin, Antimony, Molybdenum, and Chromium. These elements, often remnants of previous alloying processes, can drastically alter the steel’s microstructure, reducing its ductility and toughness and making it prone to failure during automotive crashes.

Aerobase Innovations AB is tackling this challenge by developing advanced material models to predict how these trace elements affect steel during manufacturing and in-service conditions, such as deformation-induced failure or welding. By modeling how trace elements influence microstructural evolution, we aim to optimize the design and performance of automotive components made from recycled materials.

Key Innovations by Aerobase in the CiSMA Project

1. Modeling Deformation-Induced Failure

Aerobase has pioneered the development of a physically-based multiscale model that predicts deformation-induced failure in recycled automotive materials. This model considers the anisotropic effects caused by the distribution and alignment of trace elements, non-metallic inclusions, and microstructural banding. By incorporating probabilistic functions, we can account for variability in material properties, enabling the design of more resilient components that can withstand the detrimental effects of impurities. This innovation addresses how trace elements like copper and tin promote early failure and reduce plasticity in materials, which is critical in crash situations. The model will allow the automotive industry to virtually simulate crash scenarios with recycled materials, reducing reliance on costly physical testing.

2. Modeling Phase Evolution Kinetics

Welding is crucial in automotive manufacturing, and trace elements in recycled steel can significantly affect weldability. To address this, Aerobase is developing a phase evolution model that predicts how these trace elements impact phase transformation during welding processes. This model helps optimize the weldability of recycled steel by analyzing how impurities like sulfur, phosphorus, and antimony lead to brittle phase formation and grain boundary segregation. By integrating advanced thermodynamic modeling tools like CALPHAD, we can predict changes in phase transformation temperatures and guide how to adjust welding parameters for better material performance. This innovation will enhance the reliability and performance of welded structures in automotive applications.

Commercialization of Innovation: SafeLight and Phases

Aerobase Innovations AB is already commercializing these breakthroughs through its SafeLight product line, which includes the deformation-induced failure model. This allows automotive manufacturers to simulate and optimize the performance of components made from recycled materials, improving safety and sustainability. Additionally, Aerobase plans to integrate the phase evolution library into its offerings, providing a comprehensive welding and material phase analysis solution.

Real-World Applications: Collaborating with Market Leaders

As part of the CiSMA project, Aerobase is collaborating with industry leaders like Volvo Cars and Electrolux to implement these innovations in real-world applications. Our material models are tested in simulated crash scenarios involving recycled steel components, such as door frames and stiffener beams. These simulations not only test the mechanical performance but also consider the effects of welding variability and phase evolution on the overall strength and resilience of the components.

By partnering with end-users like Volvo and Electrolux, Aerobase ensures that its solutions are tailored to the specific needs of the automotive and consumer goods sectors, helping accelerate the adoption of recycled steel in high-performance applications.

Looking Ahead: A Sustainable Future for Manufacturing

Aerobase’s contributions to the CiSMA project represent a significant step towards a sustainable future in manufacturing. By developing advanced models that enable the use of recycled materials without compromising safety or performance, we are helping the automotive industry meet its sustainability goals while maintaining high-quality standards.

As we continue to refine and expand our material modeling capabilities, Aerobase Innovations AB is committed to driving innovation that supports the circular economy and reduces the environmental impact of manufacturing processes. Together with our partners in the CiSMA project, we are paving the way for a greener, more sustainable automotive industry.

The European Health and Digital Executive Agency (HaDEA) funds the project. The project page is here.

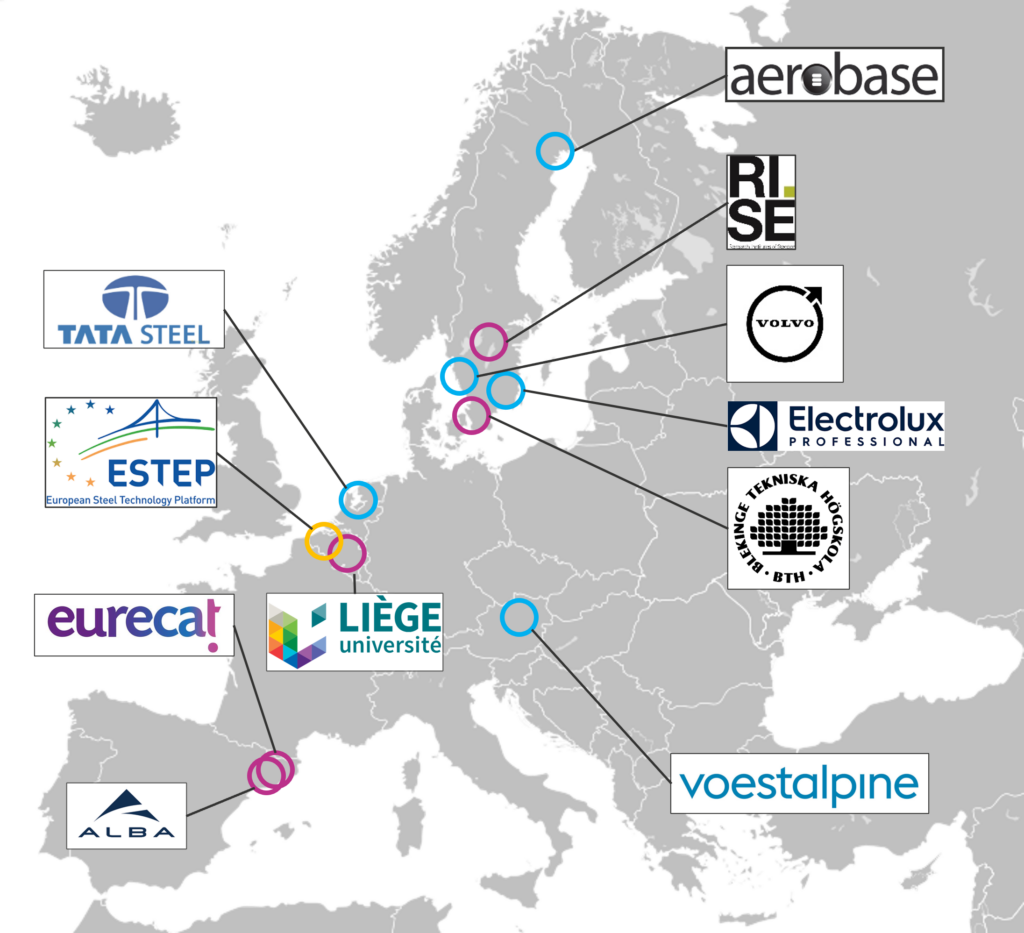

Consortium:

The CiSMA consortium includes several key partners from across Europe, each bringing unique expertise to the project. Eurecat – Technology Centre (Spain) coordinates the project with the following partners: Tata Steel Nederland, voestalpine Steel Division, Volvo Cars, Electrolux Professional Group, RISE Research Institutes of Sweden, Blekinge Institute of Technology, Consorcio para el Desarrollo Sostenible de la Ecorregión Andina | CONDESAN, Aerobase Innovations AB, ESTEP AISBL, CSIC, and the University of Liège.

Connect 🔗contribute.

Are you interested in learning about CiSMA or participating in its various phases? Connect with us on LinkedIn and share your thoughts.